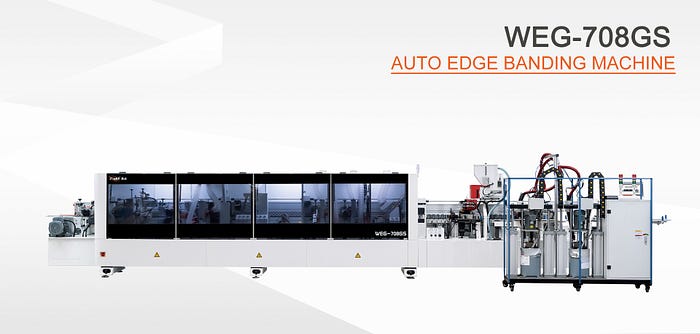

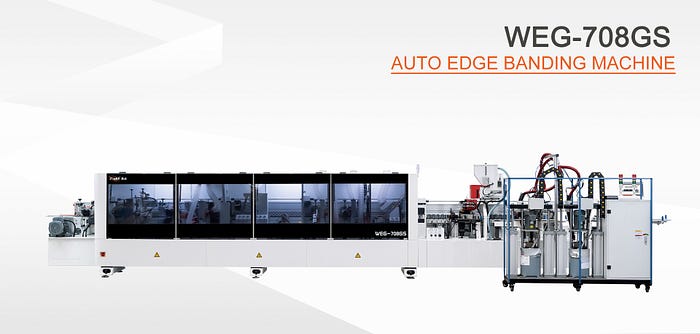

In the ever-evolving realm of woodworking, technological advancements continue to redefine efficiency and precision. One such innovation making waves in the industry is the Auto Edge Banding Machine. This cutting-edge device has revolutionized the way craftsmen approach their projects, offering a seamless and efficient solution to the age-old challenge of edging and finishing.

The Auto Edge Banding Machine is a marvel of engineering, designed to streamline the process of applying edge banding to various types of woodwork. Edge banding, the technique of affixing a thin strip of material to the exposed edges of wood panels, not only enhances the aesthetic appeal of the final product but also provides durability and protection against wear and tear.

One of the standout features of the Auto Edge Banding Machine is its automation capabilities. Unlike traditional methods that required manual application of edge banding, this machine automates the entire process. This not only significantly reduces labor costs but also ensures a consistent and high-quality finish across all pieces.

Precision is a hallmark of the Auto Edge Banding Machine. Craftsmen can program the machine to handle different edge banding materials, thicknesses, and designs with remarkable accuracy. This versatility allows for a wide range of applications, from simple straight edges to intricate and complex designs. The machine’s precision contributes to a flawless finish, meeting the exact specifications of each woodworking project.

Efficiency is another key advantage offered by these machines. The automation not only speeds up the production process but also minimizes material waste. The machine optimally utilizes edge banding materials, reducing the environmental impact and lowering overall production costs. Woodworkers can now maximize their output without compromising on quality.

The Auto Edge Banding Machine is also celebrated for its user-friendly interface. Manufacturers have invested in intuitive control systems, making it easy for operators to set parameters, monitor the process, and make adjustments as needed. This ensures that even those new to the technology can quickly adapt and start producing professional-grade results.

In addition to its operational efficiency, the machine’s durability and reliability are noteworthy. Built with robust materials and cutting-edge technology, the Auto Edge Banding Machine is designed to withstand the demands of industrial-level production. This reliability translates into less downtime, ensuring that woodworking operations can run smoothly and meet deadlines consistently.

Furthermore, the Auto Edge Banding Machine contributes to a safer working environment. By automating the application process, the risk of injuries associated with manual handling of tools and materials is significantly reduced. This promotes a healthier and more secure workplace for craftsmen.

The impact of Auto Edge Banding Machines extends beyond the production floor. The increased efficiency and precision result in a higher quality of finished products, ultimately enhancing the reputation of woodworking businesses. Clients and customers can now expect consistently superior craftsmanship, leading to greater satisfaction and repeat business.

In conclusion, the Auto Edge Banding Machine stands as a testament to the transformative power of technology in the woodworking industry. By automating and optimizing the edge banding process, this machine has become an indispensable tool for craftsmen seeking efficiency, precision, and reliability. As the woodworking landscape continues to evolve, these innovative machines are poised to play a central role in shaping the future of the industry.

| Welcome to Heyshell Games Forum (http://bbs.heyshell.com/) | Powered by Discuz! X2.5 |