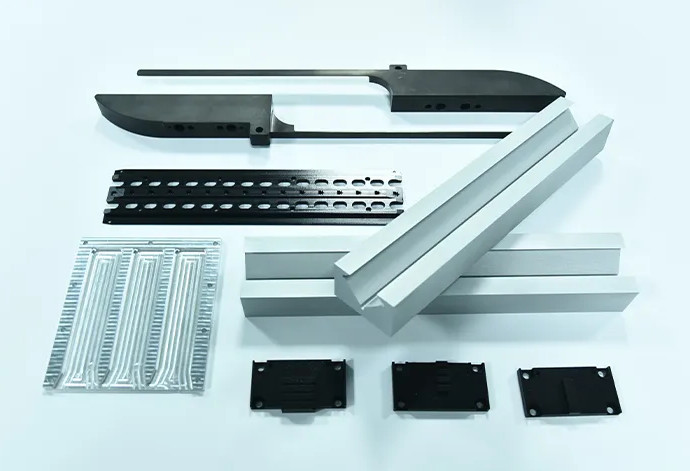

In the realm of modern engineering and manufacturing, aluminium precision parts stand out as versatile components crucial to a myriad of industries. These meticulously crafted pieces serve diverse functions, ranging from structural support to aesthetic enhancement. With the capability to be shaped into intricate forms and adorned with various surface treatments, aluminium precision parts exemplify innovation and functionality.

One of the key attributes of aluminium precision parts is their adaptability to different surface treatments. Among the array of options available, gold plating, nickel plating, Teflon plating, silver plating, oxidation, and hard oxygen treatments are prominent choices. Each treatment offers distinct advantages, catering to specific requirements of performance, durability, and aesthetics. Gold plating, for instance, not only imparts a luxurious appearance but also provides excellent corrosion resistance, making it ideal for applications in electronics and jewelry. Nickel plating, on the other hand, offers enhanced durability and wear resistance, often utilized in automotive components and machinery. Teflon plating, renowned for its non-stick properties, finds its niche in industries requiring friction reduction and chemical resistance, such as aerospace and food processing. Silver plating, prized for its conductivity and antimicrobial properties, is commonly employed in electrical contacts and medical devices. Meanwhile, oxidation treatment creates a protective layer on the surface, increasing resistance to corrosion and improving aesthetic appeal. Hard oxygen treatment further enhances the hardness and durability of aluminium parts, extending their lifespan in demanding environments. Beyond functional enhancements, surface treatments also play a significant role in defining the visual characteristics of aluminium precision parts. The choice of plating or coating can transform the appearance of a component, elevating its aesthetic appeal and aligning it with the desired design aesthetics. Whether it’s a sleek metallic finish, a vibrant gold hue, or a matte texture, surface treatments offer endless possibilities for customization and creativity. Moreover, the versatility of aluminium precision parts extends beyond their surface treatments to their inherent properties. Aluminium’s lightweight nature, combined with its exceptional strength-to-weight ratio, makes it an indispensable material across various industries. From aerospace engineering to consumer electronics, aluminium precision parts contribute to the development of lightweight yet robust products, enhancing performance while minimizing energy consumption and environmental impact. Furthermore, the machinability of aluminium allows for intricate shaping and precise detailing, enabling the creation of complex geometries essential for modern engineering designs. Whether it’s CNC milling, turning, or extrusion, aluminium precision parts can be fabricated with utmost accuracy, meeting the most stringent tolerances and specifications. In conclusion, aluminium precision parts represent a fusion of innovation, functionality, and aesthetics. Their ability to undergo diverse surface treatments enhances both their performance and visual appeal, making them indispensable in numerous industries. From enhancing conductivity to reducing friction, from increasing durability to elevating aesthetics, aluminium precision parts continue to push the boundaries of what is achievable in modern engineering and manufacturing. As technology advances and demands evolve, aluminium precision parts will undoubtedly remain at the forefront of innovation, driving progress and innovation across industries worldwide.

|